ARTICLE SUMMARY

Understand the definition, fundamentals, and benefits of process improvements for your business processes.

What is process improvement?

Process improvement, also known as business process improvement, refers to the practice of finding ways to make existing processes faster, more accurate, more efficient, and more reliable. This practice should be considered an ongoing exercise rather than a one-time action.

Start building more efficient workflows with the Citizen Developer’s Guide to Workflow Optimization

What is process improvement in business?

Process improvement in business is usually a practice that aims to identify problems or opportunities in existing processes, create solutions, and then apply those solutions to processes so as to optimize them.

Why is process improvement important?

Every company relies on different types of business processes to power its operations. Whether it’s your employee onboarding, issuing or receiving payments, or resolving issues in IT systems, there is a process behind everything your business does.

If your business processes take a long time to complete, require more resources than planned for, or produce inconsistent results, you’re likely experiencing a process breakdown that’s making your business operations less effective. Inefficient or inaccurate processes cost businesses up to $1 trillion each year. Process improvements can solve that.

Process improvement benefits

Process improvements goals are typically a combination of any of the following: improve productivity, gain agility or visibility in order to adapt to market changes, streamline workflows, increase profits, patch security gaps, achieve operational excellence, or create better user experiences — both internally or externally.

There are several ways process improvement can benefit your business, including:

Time savings

A fundamental benefit of process improvement is a decrease in the time it takes to complete tasks through streamlining and reducing the number of steps involved.

Better results

Process improvements instigate better results like enhanced employee performance or clearer process milestones and tasks.

Improved customer satisfaction

Faster and more effective customer service, a high quality standard, and hitting every deadline: it’s all possible with process improvement and can help improve customer outcomes across the board.

Increased transparency and alignment

Understanding and clarifying all stages in a process ensures that all your team members know their responsibilities, and it makes it easy for them to share information and collaborate efficiently.

Reduced waste

Cutting out redundant steps or entire processes that consume valuable resources is an easy and effective way to ensure you’re wasting as little time and money as possible.

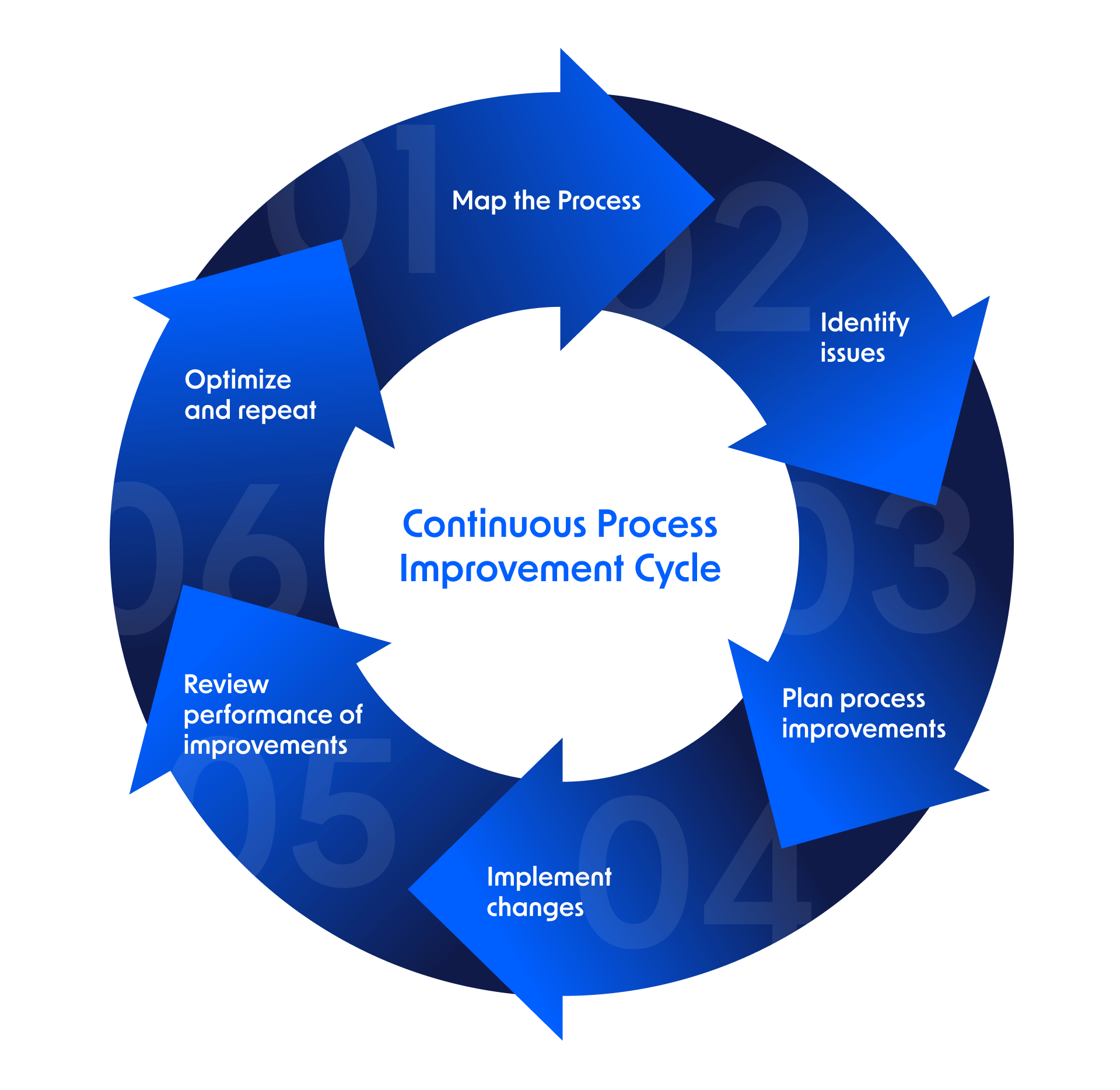

What can continuous process improvement do for your business?

Continuous process improvement helps solve process problems by breaking up improvements into smaller, more manageable chunks that occur on a rolling basis, rather than in large sweeps or when they become too large to manage. This not only saves companies time and resources, but it also helps teams get ahead of potential, process-specific issues before they become larger company-wide risks.

Rather than wait for something to go from bad to worse, continuous process improvement encourages teams to continuously seek and identify opportunities to strengthen or repair existing business processes. And by implementing continuous process improvements as an ongoing practice, business processes are able to run in a more efficient and effective manner.

Example of process improvement

In order to understand the effectiveness of a process improvement, consider the customer onboarding process.

The customer onboarding process is used to welcome new customers, teach them about your product or service and how to use it, and how to request support. When done correctly, the customer onboarding process ensures that new customers get the most out of what you offer, makes their customer experience as smooth as possible, and creates long-term success with your product or service.

A common challenge in customer onboarding is information overload, leaving new customers struggling to digest all the knowledge shared, or, worse, even ignoring much of it. This leads to inconsistent results when it comes to customer satisfaction and an inefficient onboarding process — and can create issues for your team, like managing extraneous materials that cost extra time and money to distribute.

Rather than rewrite the customer onboarding process, here are two simple process improvements that can eliminate bottlenecks and improve the customer experience:

- Create a personalized customer onboarding journey to eliminate redundant or irrelevant information. By tailoring the process in a standardized way, different customers can receive different types of information based on their specific department, use case, or needs.

- Use a business process management (BPM) platform to codify and optimize the customer onboarding process. With a BPM, you can customize and automate the process so that customers receive the correct materials based on their needs. Plus, setting up a workflow in a BPM platform allows you to transparently show the progress of each customer’s onboarding, and clearly delineate responsibility for each customer with built-in metrics, logging, and reporting options.

Read more about process improvement examples.

Learn to optimize workflows for speed, accuracy, and exceptional user experiences with The Definitive Guide to Workflow Management

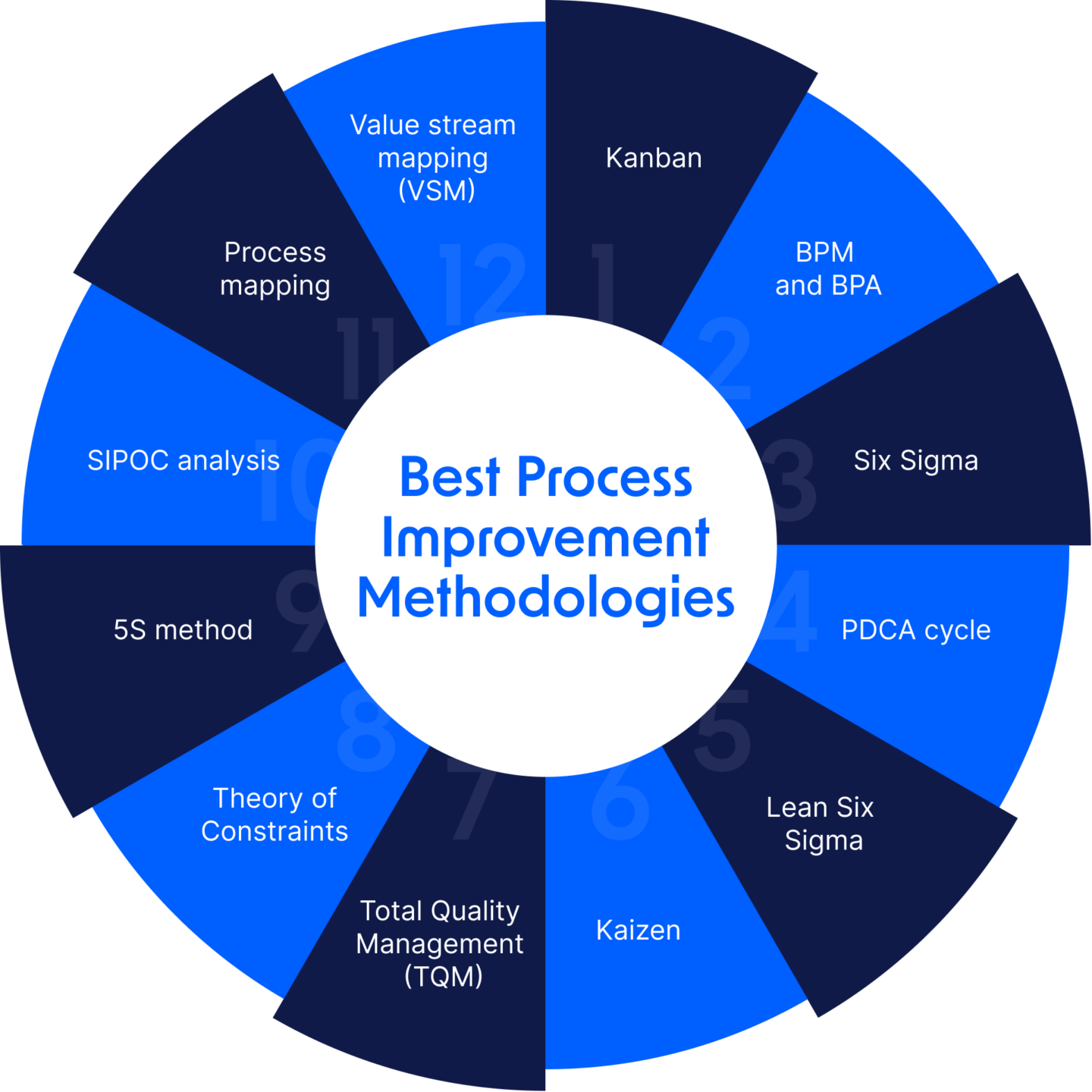

Process improvement methodologies

Process improvement is done using methodologies that help teams evaluate the state of current processes and identify opportunities to improve them. To help with your process improvement plan, here are some common process improvement methodologies:

PDCA Cycle

PDCA stands for plan, do, check, act. This method is most commonly used for the continuous improvement of processes and products. The four-step model works best as a project planning tool and cycles through each step (plan, do, check, act) in a circle, over and over again in an endless loop, so as to maintain continuous improvement.

If this sounds like the ideal method for your process improvement plan, check out our free PDCA template to get started.

Kaizen

Kaizen is a Japanese business philosophy that centers on continuously improving operations or processes. At its core, Kaizen is about having a mindset of continuous improvement and is a simple yet pivotal concept to keep in mind.

TQM

Total quality management is an approach to creating long-term business success via customer satisfaction. This means that the purpose of improvements ultimately ladder up to one thing: providing the best experience for customers.

With TQM, companies will focus on improving processes, products, services, and their own culture so as to become customer-centric. TQM has eight primary elements:

- Be customer-focused.

- All employees are involved and should work toward being a customer-first operation.

- Defined and streamlined processes are essential.

- System integration is needed to connect all processes and departments.

- TQM requires a strategic and systemic approach.

- Continuous improvement is necessary.

- Decision making should be data-driven.

- Effective communication is the foundation of TQM.

Theory of Constraints

The Theory of Constraints is a process improvement methodology that centers on a single truth: quickly identify and manage bottlenecks that get in the way of goals and process efficiency.

According to the Theory of Constraints Institute, leading improvement efforts through this method is normally the fastest and most effective way to improve profitability.

5S

5S is a methodology that uses a list of five Japanese words:

- Seiri (translation: sort).

- Seiton (translation: set in order).

- Seisō (translation: shine).

- Seiketsu (translation: standardize).

- Shitsuke (translation: sustain).

Together, they describe how to best organize a business or process for better efficiency and effectiveness.

Learn more about how to use this methodology and implement it within your own organization with Pipefy’s free 5S methodology template.

SIPOC analysis and process mapping

SIPOC stands for suppliers, input information, process, output, and customers. SIPOC diagrams are detailed high-level process maps. This helps identify relevant elements of a process before teams start working so as to better understand how processes should work.

Once the SIPOC analysis is completed, it’s time to begin process mapping. At this stage, the high-level process map becomes a much more detailed process map that outlines every person, department, action, or procedure that happens between Point A (starting point) and Point B (ending point).

VSM

Value stream mapping displays all steps required to deliver value to the customer, whether they are external (customers) or internal (employees). A value stream flowchart will include each and every step required to complete a process.

VSM helps teams see the big picture of your processes and pinpoint everything that can be improved.

Kanban

Kanban is a great way to encourage feedback and map out any continuous process improvements by visualizing a board with dynamic columns that make all tasks within a process and their status clear. This brings visibility to all improvements or tasks.

If work flows smoothly through a process and that is visually apparent, then the process is working. But if the process is not flowing and backlogs become apparent throughout the process, then it becomes clear that something is wrong and a process improvement is in order.

Here are two great pieces on the benefits and use of Kanban:

Find the right automation solution for your process improvement strategy with the Buyer’s Guide to Automation Platforms

How to identify process improvement opportunities

Processes that are prime for improvements typically share these qualities: they are inefficient, they are time-consuming, they lack standards and procedures, and they contain bottlenecks that either slow down the rate at which work is completed or totally bring workflows to a halt.

When combined, these issues can affect critical functions like communication and collaboration.

Read more about lean process improvement.

How to improve a process

Keeping everything we’ve just discussed in mind, here are a few ways to put information into action and start improving processes.

1. Pinpoint the problem

First, determine what the problem is. Is there a breakdown in communication? Are there bottlenecks delaying workflows? Is the challenge related to technology or to team bandwidth?

2. Identify the process(es) you want to focus on

Once you understand what the process problem is, you can jump into assessing the problem processes.

3. Analyze how the problem affects the people involved

Measuring the impact of an ineffective process is a key step in determining how to best approach the improvements. If you have access to process dashboards or reporting features, pull data to inform this step and better understand the potential reach of improvements.

4. Determine solutions and implement them

This is a team effort, so make sure to include everyone involved in the process you’re improving. Leveraging software to help with the process mapping can be especially helpful.

Ready to start mapping your improvements? Check out our free business process mapping template.

5. Implement standards and procedures

A common process problem is a lack of standardization. Solve this potential pitfall by creating a clear map of how processes work and how to best work within the process, so as to avoid any internal confusion.

At this point, also consider creating a standard for when process improvements will be assessed. This will provide insight into whether the improvements are helping or not.

6. Communicate with team members

In order for the improvements to have an impact and function appropriately, it’s important to communicate changes to the team members involved.

7. Conduct process improvement reviews regularly

This one speaks for itself, but process improvements should happen more than once. After letting the updated process run for the amount of time established (this can be anywhere from three to six months), review the results and fill any remaining gaps accordingly.

5 tips to master process improvements

1. Start small

The greatest challenge to improving business processes is feeling overwhelmed before the improvements even start. This attitude can affect how well the improvements are implemented and can tarnish stakeholder buy-in.

Limit the number of improvement initiatives being considered for implementation, and start at a smaller scale before taking on larger improvements. Whether you start with a single workflow or a single process, first identify which areas of your business processes are high priority and need immediate attention.

2. Create a detailed and documented plan

Without a detailed plan that outlines how improvements will be implemented, process improvements may not be implemented properly, errors may be introduced, and anticipated results may not occur.

Ensure that all process improvement initiatives don’t start without a clear process improvement plan and that all the necessary details, such as due dates, deliverables, roles, and accountability are listed and readily accessible.

3. Use the right technology

Adopt a tool that best suits your needs in order to help you track and manage your improvement initiatives. A low-code business process automation solution with a visual user interface makes it easy to create and optimize processes and workflows easily, without relying on IT. For an additional level of control, look for software that can easily integrate with your existing tech stack to enhance control and visibility over your business processes.

4. Establish standards and procedures

Once improvements have been documented and shared, it’s also important to establish standards and procedures in order to properly manage process improvements. This will also ensure the quality of your improvement initiatives.

As improvements are implemented, be sure to update the standards and procedures as well, and notify all people involved with the process so they’re aware of changes.

5. Automate, automate, automate

Business process automation improves process efficiency by standardizing and recurring tasks related to managing process improvements. Improve the

In addition to automating notifications or email communications, process automation also consolidates data, dissolves communication silos, and improves accuracy, speed, and precision by reducing manual work and using rules to sort and route items through workflows.

Business units need agility. IT needs control. Learn how no-code delivers both in No-Code Automation: Good for Business, Great for IT

Encouraging process improvement

It’s important to ensure that teams feel the responsibility to optimize and improve their business processes. To engage people toward improving processes, let them know that their input is valued and taken into consideration — not only towards processes in their own area but in the whole company.

In addition to letting them know that their voice matters, managers and leaders should also give teams the space and liberty to make suggestions without fear of reprehension. With the encouragement to improve their own processes, teams will be more likely to want to improve processes continuously.

Process improvement with no-code automation software

Unoptimized processes cost businesses up to $1 trillion each year, either through inefficiency, poor user experiences, or increased risk. By implementing a process improvement strategy, leaders can resolve current problems with processes and anticipate issues that may arise in the future.

One of the most versatile and effective tools available for process improvement is no-code automation software. These solutions deliver a range of process improvement features that are easy for business teams to use, and secure enough for IT teams to approve. Business teams can model, modify, and monitor processes in real-time, in response to competitor activity or customer feedback. IT teams are relieved of the burden of resolving every change request.

Low-code automation integrates with the components of the existing tech stack to provide seamless user experiences and resolve data silos. Above all, no-code tools provide the flexibility needed to improve and orchestrate any type of process, in any department. Now and in the future.