A company’s procurement department is driven by various processes and teams, including purchasing and accounts payable. One of the tactical processes leveraged to realize strategic goals is the source-to-pay process.

Here’s everything you need to know about source-to-pay, from what it looks like in practice to how source-to-pay automation can improve procurement efficiency.

Definitive Guide to P2P OptimizationDownload now

What is the source-to-pay process?

Source-to-pay (also known as S2P) is a process within procurement that encompasses activities associated with business and supplier interactions. This includes:

- Sourcing

- Solicitation

- Issuing payments

- Supplier management

- Vetting new suppliers

- Negotiating terms

- Setting up contracts

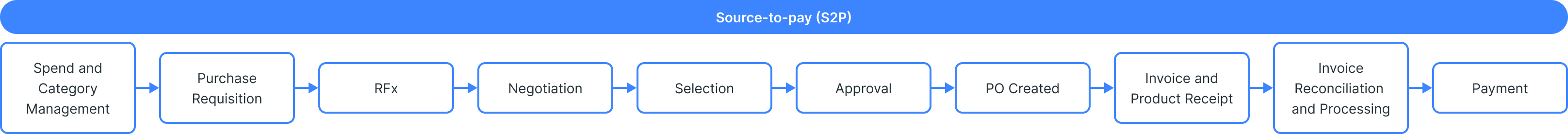

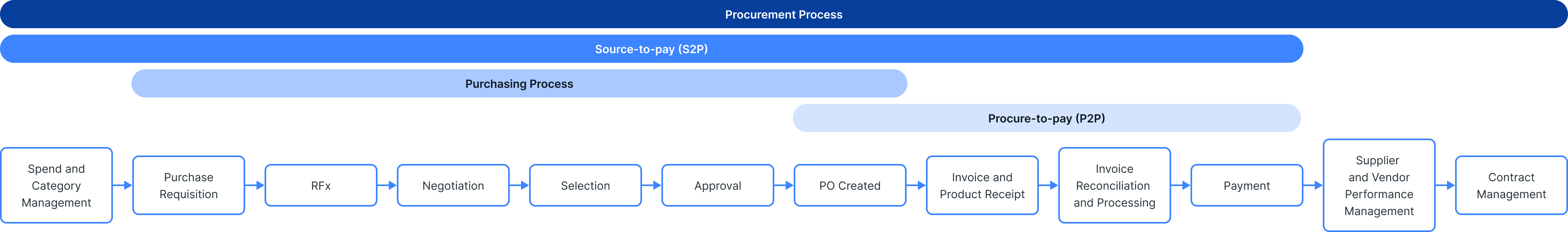

Source-to-pay is similar to procure-to-pay (P2P), but it differs slightly. S2P begins much earlier than P2P within procurement and encompasses many additional steps than P2P. While S2P is focused on integrating and streamlining supplier interactions, P2P is focused on integrating and streamlining purchasing and accounts payable activities.

Learn more about the difference between source-to-pay and procure-to-pay.

When is source-to-pay used?

As its name suggests, S2P’s key aim is to source the best suppliers to meet business needs, from purchase request sourcing to issuing final payments. Typically, the source-to-pay process is used to fulfill needs like finding new suppliers that offer lower prices, better terms, or goods/services not offered by current suppliers.

This is essential for strategic sourcing, a critical process for developing various channels of supply to help procurement teams leverage their purchasing power and secure better deals.

Because this process ends when payment is issued, businesses adopting a source-to-pay model often use dedicated software to integrate procurement departments with accounts payable (AP) for end-to-end centralization of business and supplier interactions.

S2P benefits

S2P saves time, simplifies processes, provides visibility into supplier performance, improves compliance, and saves money by streamlining and automating tasks otherwise performed manually, such as RFx requests, invoice processing, and managing supplier databases and interactions.

This not only improves procurement efficiency, but it also conserves valuable employee time previously spent on managing painstaking spreadsheets. It also reduces costly errors or delays due to inaccurate financial forecasting or late payments and approvals.

With S2P, procurement processes are streamlined into a single workflow so the various systems, stakeholders, and interactions are no longer siloed or disconnected.

S2P vs. traditional sourcing

Traditional sourcing methods treat procurement as a series of unrelated tasks with approvers operating within different branches of the same business and using different software with little or no interaction.

Businesses that choose an S2P procurement approach aim to:

- Create more seamless integration between cross-team processes (particularly purchasing and AP)

- Find new cost-saving opportunities

- Identify vendors with the shortest fulfillment times

- Build more transparency into each step of their own procurement process, from beginning to end

What are the S2P steps?

The cycle of S2P processes varies slightly depending on the business, procurement category, or industry, but they typically contain these 10 key steps.

1. Demand or need established

Whether it’s a purchase request or forecasted demand, a need for a product, good, or service is required In order to begin sourcing. In addition to sourcing for a request or need, demand can also include obtaining those supplies for a better price.

2. Demand or need vetted

Before the purchasing team begins sourcing, the request will need to be vetted and approved to ensure that it’s in compliance with procurement policies and a true business need.

3. Sourcing

Once the need or demand has been established as necessary, it’s time to begin the search for potential suppliers and evaluate them. S2P software can quickly identify and vet existing suppliers from your supplier database, and compare previous supplier/vendor performance, delivery time, and other essential criteria for choosing a supplier.

4. RFx and bids

Once the list of potential suppliers for the project has been finalized, the bidding process will begin. Requests for information (RFIs), proposals (RFPs), or quotes (RFQs) will be issued to determine which supplier offers the best terms, prices, and delivery timeline. They also make it easy for buyers to compare suppliers and negotiate.

S2P software automatically generates and shares these documents with suppliers and stores them securely in an eVault for easy access and visibility.

5. Supplier chosen

When bids have been completed and received, buyers must choose the best supplier for their needs by considering data such as pricing, performance, and delivery times.

6. Contract drafted and signed

Pricing and contract terms must be negotiated and agreed upon at this stage. When negotiations are complete and both parties are in agreement, the time has come to sign the contract. These steps (sharing, collecting, and storing contracts) can also be automated with S2P software.

7. Purchase order generated and submitted for fulfillment

When a purchase order (PO) and any change orders are issued and accepted, procurement enters and monitors them.

With the supplier chosen and the contract(s) signed, the purchase request will now become an official purchase order that is submitted for fulfillment. At this point, the procurement team now takes control of the process.

8. Goods received or services rendered

Once the supplier fulfills the purchase order, procurement will receive and verify that what’s been delivered or provided was done in a timely and satisfactory manner.

9. Invoice received and processed

Once the PO has been fulfilled, the accounts payable team will receive an invoice from the supplier or suppliers. The AP team is responsible for managing the full invoice processing process, from 3-way matching to approving to keeping procurement and suppliers informed on the status of invoices and payments.

10. Payment issued

After the AP team approves and reconciles invoices, payments will be issued and suppliers will be notified. The payables will be considered closed and the AP team will update the general ledger to accurately reflect the transaction.

S2P automation: What it is and why it’s essential

Source-to-pay automation refers to the use of software to digitalize workflows and manual procurement tasks. Automating procurement processes creates better visibility for all stakeholders involved and streamlines handoffs and manual activities by phasing out repetition, redundancy, and rework for employees.

Source-to-pay automation helps lower overall procurement costs and increase business savings by providing procurement process transparency and facilitating faster, more accurate supplier vetting.

Improve procurement and AP efficiency with S2P process automation

Source-to-pay automation leads to more effective supplier management, and it also helps the accounts payable department be more cost-efficient.

By centralizing processes and supplier interactions into a single agile and customizable platform, teams can streamline time-consuming and error-prone tasks by eliminating manual activities like approval requests, compiling and tracking supplier performance analytics, invoice processing, and supplier management.

This allows teams to reinvest time spent managing workarounds to rigid or manual process parameters into focusing on improving business performance. With Pipefy, source-to-pay automation is within reach.

Pipefy’s no-code framework and IT-sanctioned toolkit of features and capabilities make designing, deploying, and managing optimized procurement processes quick and easy. And with the added benefit of integrating Pipefy with your existing systems, software, and apps, expand the capabilities of your end-to-end procurement processes with stack extensibility.

By simplifying the chaos of toggling back and forth between numerous tools, time-consuming redundancies, and process inefficiencies, teams can achieve better results, build stronger and more reliable supplier relationships, and decrease financial business losses.