ARTICLE SUMMARY

If you haven’t been living in a bubble for the past two decades, you’ve probably heard of Amazon.com and its

If you haven’t been living in a bubble for the past two decades, you’ve probably heard of Amazon.com and its incredible success story. The technology company is well known worldwide for its e-commerce, but what many people don’t know is that Amazon is an important Lean management case study.

Why? Because Amazon has been obsessed with four things since day one:

- Customers

- Long-term thinking

- Invention

- Operational excellence

So How is Amazon Lean?

Born on the internet back in the 90s, Amazon was disruptive from the start. Jeff Bezos—the one and only Amazon CEO—believed in the power of a customer-centric company, ignoring the media’s pessimistic attitude toward his strategies and not giving the competition a second thought.

Having a Lean mindset, Bezos has built a strong culture in Amazon. Its core mission is to offer the customer exactly what they expect and need. Apart from that, the employees are empowered to own their actions and escalate to higher standards. Bezos believes in the power of having hands-on senior managers that actively improve the business by correcting problems in their root cause.

This mindset made Amazon the technology giant that it is today. And it all started with the strong belief that by delivering value to the customers and improving continuously, you can build great things. By the way—this is the Leanest thing!

Forget the Manufactures, Lean can be Applied Everywhere

Lean is a Japanese philosophy that was developed in the industry after World War II. Taiichi Ohno, a Toyota engineer, was looking for ways to rebuild the company so after visiting successful plants from other companies and spotting improvement opportunities, he developed the Toyota Production System (TPS)—also known as Lean manufacturing. The main goal was to continuously improve the way the company worked, eliminating waste and creating customer value.

Toyota’s rebuilding was remarkable, so other companies started adopting Lean practices over time. As it got more popular, organizations outside the manufacturing world started understanding how Lean could be beneficial to other niches as well.

That’s where Amazon stands. Jeff Bezos already built the tech company with a Lean mindset, and later when Marc Onetto joined the team to lead as SVP of Operations and Customer Service (previous Senior Executive at GE), Lean practices became a formal procedure at Amazon.

Crazy about the Customers

Yes, they’re obsessed with their customers—and that’s great! They always understood the importance of adding value to their clients and that’s the Leanest practice possible. Lean is all about generating value, which means delivering something the customer actually wants to pay for.

Likewise, continuous improvements is another Lean pillar, and Amazon masters that. Bezos always knew that he didn’t want to offer something wasteful to his clients, so one of the practices that enhances customer experience at the e-commerce is a Lean tool called the Andon System.

The Andon System—or the Andon Cord—is the practice of empowering the employees to “stop the line.” In an industry, pulling the Andon Cord means stopping the manufacturing process to adjust possible harmful situations to the company’s value. In Amazon, it means that customer service agents can take products off their website if they receive recurrent complaints, and they don’t need any senior clearance for that.

They are so crazy about their customers that absolutely everything they do is thinking about their experience, even if it means lowering margins or opening more distribution centers to be closer to their clients.

Do Like Amazon and Become Lean Today! Try Pipefy for Free

Professional Long-Term Thinkers

Thinking from a broader perspective is also one of Lean’s principles: “Base your management decisions on a long term philosophy, even at the expense of short term financial goals.” according to Jeffrey K. Liker in “The Toyota Way.” And that’s exactly what Amazon does.

It’s clear how Jeff Bezos has always seen the bigger picture. He has consistently based his decisions according to his client’s needs, even if it wasn’t immediately profitable.

Amazon was founded in 1994, but its first profit was only in 2002, almost 10 years later…talk about long-term thinking. Bezos was constantly questioned by the media and even investors if Amazon was going to thrive some day. Fast forward more than 20 years later and Amazon is the largest marketplace (and Bezos is the richest man) in the world.

Amazon also practices autonomation—or Jidoka, in Lean terms—mixing intelligent and human automation. At Amazon, Jidoka helped them to grow from an online bookstore to the store of everything by automating everything possible, leaving the complex and creative work for the humans.

By doing that, they were able to reduce waste, such as unnecessary or wrong Andon Cords and inventory issues.

Keep in mind: Every little act is worth it if you are reducing waste, adding value and continuously improving. In Lean, there are no small changes—little by little you’ll make great transformations!

Passionate for Inventions

You can’t deny—passion for invention is in their DNA. They like to say that every day is “Day 1.” New things are created daily and they value and encourage innovation, so anyone in the company can create and suggest ideas to improve customer experience.

And guess what? This practice is also related to Lean’s values! Lean and Amazon believe in empowering employees to bring new ideas as often as possible. The Japanese philosophy says that companies should continuously improve by challenging everything and always engaging employees to be better every day.

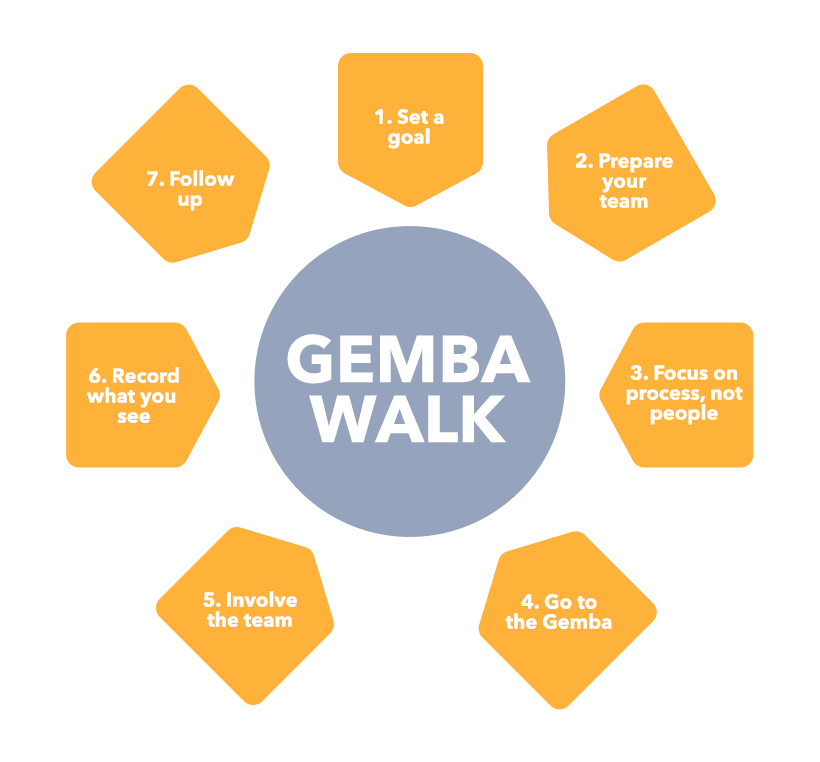

One way of involving everyone in the process is the Gemba Walk. In Lean, Gemba means the place where the value is created. Thinking of a manufacturing, it’s the production line. But when applied to Amazon, Gemba is the customer service department.

So how does the Gemba Walk work? Simple! In a manufactory, the person or the team in charge of auditing the Gemba goes to the plant and observes how the production progresses. They make notes and watch the whole process in order to spot areas of improvement.

In the tech company’s case, senior managers are inspired to work in customer service at least one day a year. By doing that, they are exposed to frontline events, which allows them to experience a different reality, spot problems and find creative solutions.

The Gemba Walk is a simple action that makes a massive impact on the process of continuously improving, which leads us to the next Amazon principle:

Committed to Operational Excellence

To provide real value to the customers, everyone in the company must be committed—it’s a cultural matter—and here is where Kaizen, one of Lean’s pillars, is the most effective.

Kaizen means “change for the better”. It aims to create a culture of continuous improvement and to build a learning organization. According to Lean’s principles, some practices to achieve these goals are:

- Develop and empower your people

- Be transparent

- Be present—go to the Gemba

- Involve the whole company

- Listen to the voice of the customer

- Eliminate waste, add value and improve continuously

Isn’t this just screaming Amazon? They’ve mastered Kaizen since the beginning—even when Lean wasn’t officially at the company.

The fact is that customer-centric companies are already one step further in the Lean transformation; they only need to improve and use the right tools. In Amazon’s case, they focused on standardizing processes. By doing that, they became able to track all abnormalities and eliminate them.

Simon Dawson/Bloomberg via Getty Images

At the tech company, there’s even a Kaizen program in which employees work in small teams to identify gaps, find ways to improve processes and influence everyone to build a better working environment.

Keep in mind: If you really want to improve your company through Lean, you must involve—and mix everyone! At Amazon, the Dream Kaizen Team is composed of frontline workers, engineers and executives. How is your company’s Dream Kaizen Team formed?

Building a Leaner Future

Seeing how Lean played a key role in Amazon’s success, it’s clear that the manufactory-born philosophy is actually useful for all niches and industries.

Amazon was already built with a Lean mindset, but it doesn’t mean that different companies can’t adapt to a new style. It becomes a satisfying process when you get your team together to build something great and strive to better yourselves and your business every day!

To begin your Lean journey and be as successful as Amazon is with the Japanese philosophy, always remember to:

- Identify the bottlenecks in your processes

- Eliminate every kind of waste possible

- Standardize and automate tasks—remember Jidoka

- Think of how you can work smarter, not harder

- Inspire your employees and colleagues to be an active part of the Lean philosophy

- Go and see for yourself—do the Gemba Walk no matter which position you hold in the company

- Don’t be afraid of exploring and using different Lean tools

- Prioritize your customer’s needs—add real value to them

- Never stop—always test, explore and reach for the stars

Also… - Read our Beginner’s Guide for Future Lean Experts

- Visit the Lean Hub

Start Your Lean Transformation Today! Try Pipefy for Free