ARTICLE SUMMARY

Kanban is a Lean management tool that allows you to fully visualize the status of your processes through a board with dynamic columns that make all tasks and processes steps clear. Everyone can see what has to be done, who is doing what and what is already done. We can say that Kanban is a way to reveal workflow bottlenecks and inefficiencies, granting you the power to solve them faster and deliver consistent results to the internal and external customers of the company.

Kanban is a tool that allows you to fully visualize the status of your processes through a board with dynamic columns that make all tasks and process steps clear. Everyone can see what has to be done, who is doing what and what is already done. In a few words, Kanban is a management system that enables a visual representation of workflows, based on the Lean methodology.

Do you want to learn about Lean first? Check our Beginners Guide for Future Lean Experts!

We can say that Kanban is a way to reveal workflow problems and inefficiencies, granting you the power to solve them and deliver consistent results to the internal and external customers of the company. Great, isn’t it? This is the very core of Lean—waste reduction in order to deliver more value, always aiming for continuous improvement.

How does Kanban Work?

The most common representation of a Kanban Board is this one: a whiteboard with a ton of post-its separated into three columns: to-do (backlog), doing (tasks being done at the moment), done (finished tasks). Following this process order, you will achieve a steady flow, which yields better and faster results for everybody.

Each column is a phase of the process while each card is a task that flows through the stream. This is where the magic of the Kanban Board happens: this simple structure allows everyone to check the current status of any piece of work and optimize the flow, showing more transparency and clarity to the whole team. Bid miscommunication farewell.

Kanban works as a real-time data repository and flow mechanism, exposing bottlenecks within the system and anything else that might get in the way of a smoother process. In other words, it helps to improve your team’s efficiency.

The best thing about Kanban Boards is that they fit your needs, adapting to your process’ scenario. With Pipefy, it’s possible to create Kanban Boards for processes of different areas, such as Finance, Human Resources, Marketing, Customer Success, IT, Development and much more, you just have to customize the platform as you wish.

How to Implement Kanban?

1. Visualize Your Current Workflow

Map all processes you currently use to deliver your product or service on a visual control board. You can choose to draw it on a piece of paper or use specific software, such as Pipefy, to tackle it. Begin by defining your input and output as well as the simplified phases you take to get from point A to point B. Don’t focus too much on details, keep the big picture in mind instead.

2. Apply Work in Progress (WIP) Limits

Setting up a work in progress limit means establishing how many activities can be taken on at the same time in each stage of the process. It focuses on respecting your process limits, such as people, infrastructure and time, and also on preventing all types of bottlenecks throughout multiple processes. Pain points of overburden and unevenness must be located and eliminated.

3. Flow Management

Once you’ve mapped your process and established its WIP limits, it’s time to keep close track of it. It won’t be worth much if you create the best processes in the world on paper, but your team doesn’t follow them, right? Measuring your workflows closely allows you to have more operational control, focusing both on the quality of your deliveries as well as efficiency.

4. Constant Optimization

As we’ve mentioned in the previous step, keeping close track of your processes metrics is essential for continuous improvement — a very important aspect of the Lean methodology. Be careful, though, every time you’re considering making any changes to the board you must analyze all possible impacts this change might bring. The flow must always be standardized and updated in order to run properly.

The Benefits of Kanban. Why Adopt It?

Improvement in Production

Kanban uses Lean principles to drive down production costs by reducing waste and improving production flow. These benefits are:

- Smoother/seamless workflows

- Better inventory management

- Elimination of overproduction

- A more focused team

- Increased efficiency

- Flexibility

Lean’s main goal is to create more value with fewer resources, without compromising the productivity—objectives that Kanban overcomes. Kanban centers on working collaboratively, with everyone striving toward continuous improvement (or Kaizen, another term for Lean).

Responsiveness to Demand

Keeping track of productivity, quality and flow is essential to any manager that value numbers and wants to analyze metrics. With Kanban, production is driven by demand (that can increase or decrease according to predictable or sporadic events). Even if your demand variation seems predictable, it most likely isn’t. A Kanban Board provides a real overview of what’s happening and what’s important at the moment.

Empowerment

Kanban puts control of operations in the hands of the operators, which is great since they’re in the best position for overseeing production. They have a pulse on the real-time flow of the work and knowledge about daily operations.

Shifting accountability for monitoring the daily runs frees managers up to focus on long-term planning needs. Empowerment generates dedication and enthusiasm, lowers absenteeism, increases mutual respect among employees and enhances productivity. Everybody wins!

Self-Discipline and Quality Control

Kanban states that big tasks and goals should always be broken down into smaller, achievable tasks. By doing so, it promotes an environment focused on quality improvement. Working with fewer things at a time makes it easier to pinpoint quality control issues directly at their source.

By eliminating excess inventory, Kanban unmasks quality problems that otherwise could remain undetected for long periods of time. The system shifts the focus of workers to teamwork and quality improvement through empowerment and self-discipline.

A Quick Background: The Evolution of Kanban

Now that you’re familiar with what Kanban is and why it’s a great ally, it’s time for some history.

When developed back in 1914, the assembly line of the traditional manufacturing system of H. Ford had many issues because the focus of the structure was to produce faster and more, regardless of the needs of the customers. This generated waste at different levels.

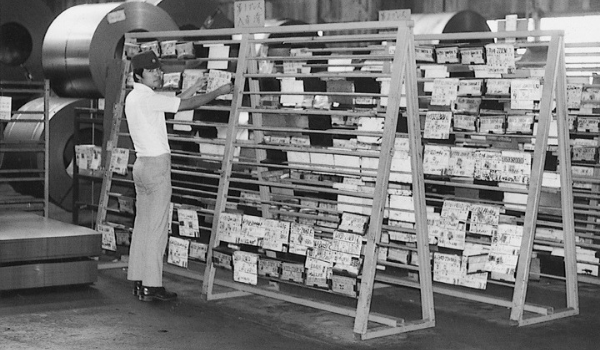

Things changed for the better when Taichii Ohno (an industrial engineer at Toyota) stepped into the scene in the 40s to present the Toyota Production System (or TPS), which introduced the Kanban Board. He developed a system to improve the entire manufacturing efficiency, prioritizing the elimination of waste to deliver more value. In other words, the Lean management system.

Ohno saw waste in all forms as the biggest villain in any production. Therefore, waste reduction became essential to get smoother processes, alongside clearer workflows. Due to the success of this recipe, TPS spread over the world and modernized itself, becoming Lean as we know today. And Kanban played a huge role in this growth!

Kanban as a Pull System

As a visual and easy tool to apply, Kanban connects perfectly to another key concept of Lean: the pull system. A pull system works on the basis of demand—which means the work is only done if there’s a real need for it by prioritizing what matters. In fact, the word Kanban means signal or card (which stands for an instruction that must be followed or completed).

To understand how a pull system works, check this comparison between pull and push systems:

Kanban Inside Lean. The Perfect Match!

Kanban is a type of management system that can be applied in different industries and not just in the manufacturing world from which it was born. Companies such as Pixar, Spotify and Zara use Kanban as part of their daily activities to closely monitor employee’s tasks, generating more value and quality with focused teams.

We can sum up Kanban as a way to organize the chaos that surrounds execution teams. It’s much more than notes on the wall or reminders to follow up, we’re talking about guidelines that provide better workflow, management overview and continuous improvement. Kanban is built collaboratively, for everyone’s benefit and better control.

Remember that any Kanban system has a life of its own and must always be tracked. Lean principles resonate within Kanban through concepts such as waste avoidance, value delivery and productivity boost. That is why you should consider Lean processes in order to extract the best out of Kanban. Congratulations! You’re now ready to take over any Kanban Board!